HD 80T Pump Performance Data Sheet

Model no 500/01/08 BR

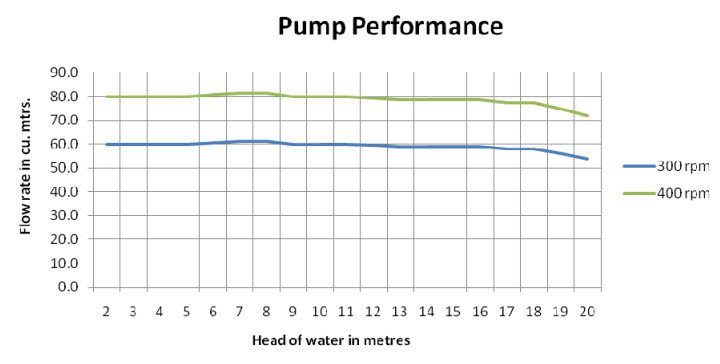

IN a test environment The HD80T has so far been run for 250 hours, at approx. 300 R.P.M. using 5.7 Kws. At heads varying up to 20 meters plus, at an average of 60 cu. meters. Per hour.

It has been calculated that a Unit with the same proportions with an intake width of 1000 mm. at 300 R.P.M. will move 504 cu. meters. (17798 Cu Ft.) per hour.

A 4000 mm wide statically mounted unit at 100 R.P.M. has the capability to move 13200 cu meters (466153 Cu ft.) per hour. As an example a pump of this size would be built into a sea wall to de-water ocean flooding

Power:

Powered by standard 100 series hydraulic motor.

The hydraulic power supply required is dependent upon output performance necessary of the pump.

The pump is designed to operate at a continuous speed of up to 400 rpm and maximum of 20 meters (65.5 ft) of output head.

To obtain this performance the hydraulic power supply requires a maximum supply pressure of 230 bar / 3336 psi with a return line pressure no greater than 20 bar / 290 psi,and flow rate of 50 liters /min

Hydraulic flow and return connections are 1/2 inch – ISO 228/1-G.

The unit is ideally suited to the power takeoff of a standard construction site digger.

Manufacturing technology:

The unique design provides a robust positive rotary displacement system that can handle liquids of the consistency of water, highly viscous solutions such as heavy fuel oil and sludges with solid lumps that would normally be manually moved to containers.

Hazardous Areas:

The body and end covers are all manufactured from bronze, the rotating elements from nitrile (a rubber compound) and the drive shafts from 316 stainless steel, all of which cannot create a spark and therefore provide suitability for use in hazardous environments.

Corrosion:

The bronze, nitrile and stainless steel are virtually untouched by the corrosive nature of sea water and the majority of chemicals in daily use.

Pump in Test Conditions:

Operated up to 2 bar / 20 meters (65.5 ft) head of water. Suction covered by up to 5 inches / 125mm of water. Medium clear water contained in specialist test tank.

Test contaminants:

Multiple plastic balls with diameters up to 12 mm (just under 1/2 inch).

Engine oil floating on surface of water.

Heavy polluted sludge containing carbon deposits, marine shells, mud, leaves,small pebbles, heavy water scale etc.

All passed through the HD80T pump without any damage being caused.

Dimensions:

650mm * 350mm * 350mm gross weight 130 Kilograms.

Outlet connection – 4” PN16 flange.

The pump has 4 no. M12 sized threaded holes situated close to each rear corner to receive fixing bracket/s and plates as required to attach the pump to the mother machine.

In addition there are 3 no. M10 threaded holes for lifting eyes on the top of the unit.

Pump Performance

Contact us if you are interested in helping take the HD80T to the next level of production.